10 Old Bailey, completed in 2009, stands within the St Paul’s Conservation Zone and sits alongside the iconic Grade II* listed Central Criminal Court. The building was originally designed to provide high-quality office space, with a focus on blending modern functionality with the historic character of the area.

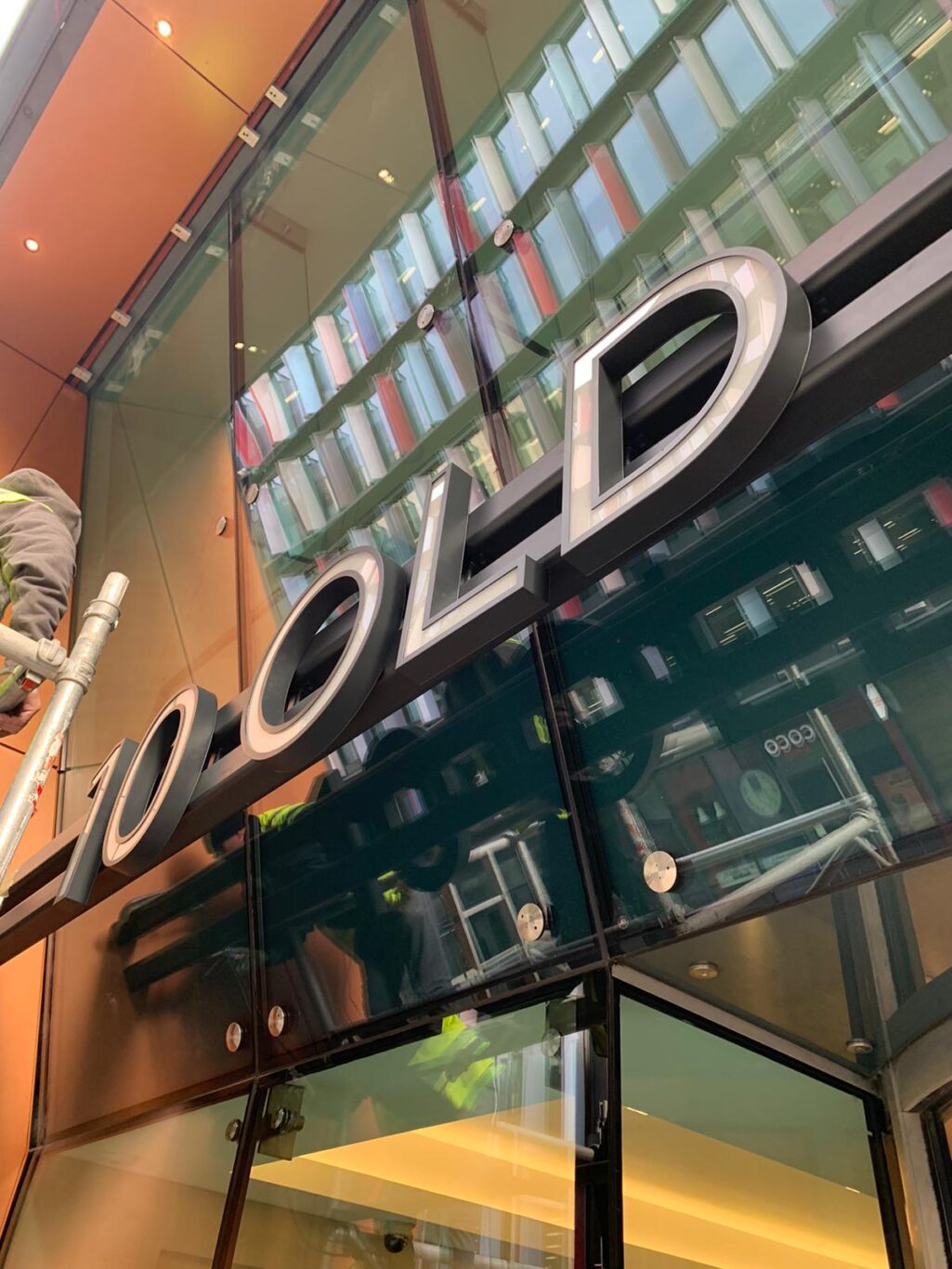

A recent refurbishment sought to elevate the building to a higher standard—differentiating it from conventional offices by introducing an executive lounge-style reception, a grand feature lightbox, and a reimagined entrance portico. These upgrades were carefully considered to reflect the building’s architectural surroundings while enhancing its street presence and internal environment.

CDC Engineering was proudly subcontracted by Whittle Interiors to deliver specialist metalwork and architectural finishes for this landmark project. Our scope included two key elements:

The result is a bold and refined building identifier that enhances the street presence of 10 Old Bailey and complements the architectural upgrades.

Through precision engineering, skilled fabrication, and close collaboration with Whittle Interiors, CDC Engineering successfully delivered architectural metalwork and signage that balance performance, durability, and design impact.

The Rosy Gold Rimex entrance cladding now provides a warm, luxurious welcome, while the illuminated “10 Old Bailey” sign serves as a defining feature of the refurbished façade.

This project stands as a showcase of CDC Engineering’s craftsmanship and attention to detail, reinforcing our reputation as a trusted partner in delivering premium architectural finishes within London’s most prestigious developments.

Nestled in the heart of London’s vibrant West End, Elsley House is a striking example of urban renewal. Originally serving the city’s historic ‘rag trade’—a hub for fashion and textiles—this five-storey building in Fitzrovia has been thoughtfully refurbished to meet the demands of modern commercial life. Today, it houses leading names from the marketing, media, and creative industries, offering them a space that combines architectural heritage with forward-thinking design.

The scale and sensitivity of the refurbishment demanded the involvement of experienced contractors with a track record of high-quality finishes and attention to detail. CDC Engineering was proud to be subcontracted to deliver key metalwork elements throughout the project.

One of the core tasks was the fabrication of all Fan Coil Unit (FCU) castings as part of the building’s upgraded heating and ventilation system. These systems were designed to be both high-performance and discreet, ensuring they integrate effortlessly into the building’s contemporary interiors. In fact, in many areas, the FCU units are so well-blended with the surroundings that they are virtually invisible—demonstrating a perfect union of functionality and design.

The FCU castings were crafted using mild steel and finished in a black powder coating, chosen both for durability and to complement the interior’s modern industrial palette. This same material and finish were extended to other custom-fabricated elements, including:

These additions help tie the building’s visual identity together, creating a cohesive and refined aesthetic throughout.

Elsley House now stands as a benchmark for adaptive reuse projects in central London—demonstrating how older commercial buildings can be repurposed to suit new uses without losing their character. CDC Engineering is proud to have contributed to this transformation, delivering expertly crafted metalwork that balances performance, subtlety, and design integrity.

Crafting Excellence: CDC Engineering’s Role in the Exchange House, London

CDC Engineering had the honor of being subcontracted by Parkeray to manufacture and install various key elements for the iconic Exchange House at Broadgate, London. We will look into the technical and creative challenges of our contributions to this landmark structure, highlighting our meticulous approach and innovative solutions.

The Exchange House is a striking hybrid of a building and a bridge, resting over the bustling rail yards of Liverpool Street Station. Its distinctive exposed steel frame spans a remarkable 78-meter stretch, supporting a 10-story office building while enabling the rail operations below to run seamlessly. This architectural and engineering marvel required exceptional precision and expertise – a challenge CDC Engineering embraced with enthusiasm.

In the reception area, CDC Engineering manufactured black aluminum-clad columns to encase 5-meter-tall glass tubes installed as part of the building’s fire safety infrastructure. These columns were designed not only for their critical function but also to align with the aesthetic vision of the architects.

We were tasked with creating 300 bespoke radiator covers for the commercial office spaces. Each cover was uniquely designed to match the dimensions of its location across various floors and rooms.

CDC Engineering crafted lift fascias for each floor, integrating signage and decorative panels with laser-cut Exchange House logos. These details served both functional and branding purposes, ensuring the building’s identity was prominently displayed while maintaining an understated elegance.

Ground floor decorative lift panels with laser cut Exchange House logo pattern.

We manufactured and installed both interior and exterior handrails with a clean, contemporary design that complemented the building’s modern aesthetic.

Additionally, we supplied a range of signage, including:

These elements enhanced navigation while reinforcing the building’s cohesive design language.

Aluminum proved to be the material of choice for this project due to its exceptional properties:

Contributing to the Exchange House allowed CDC Engineering to demonstrate our capabilities in precision manufacturing, innovative design, and seamless integration. From functional radiator covers to intricate decorative panels, every element we produced reflects our commitment to quality and craftsmanship.

The Exchange House stands as a testament to cutting-edge engineering and architectural brilliance. For CDC Engineering, it was a privilege to leave our mark on such a monumental addition to London’s skyline.

CDC Engineering specializes in high-quality metal fabrication and custom solutions for complex architectural projects. Our expertise ensures that every creation combines functionality, durability, and design excellence.

Senturion Key is a prestigious luxury brand renowned for producing the only watch in the world capable of synchronising with an entire collection of supercars. This highly exclusive and groundbreaking innovation combines the worlds of fine watchmaking and high-performance automotive engineering, making Senturion Key watches a symbol of precision, elegance, and cutting-edge technology.

(more…)Elevate Your Space with Our Bespoke Staircase and Balustrade Solutions

BW has subcontracted us to design, manufacture, and install a staircase and glass balustrade for the 8th-floor office space in the phenomenal May Axe (Gherkin) building in London.

CDC Engineering was entrusted with this prestigious project, reflecting our reputation for delivering bespoke and high-quality engineering solutions. Our comprehensive approach encompassed detailed site surveys, precise engineering calculations, and seamless collaboration with architects to ensure flawless execution.

Our engineering team conducted an extensive site survey to gather all necessary data. We performed meticulous design and engineering calculations, which included:

Working closely with the architects, we ensured that the project planning and technical aspects were aligned with the architectural vision and functional requirements. This collaboration was pivotal in achieving a cohesive and aesthetically pleasing design.

In our factory located in Shoeburyness, Essex, we manufactured a full-scale mock-up of the staircase and glass balustrade. This mock-up was presented to the BW team and their clients, allowing for thorough review and approval before proceeding with full-scale manufacturing.

Upon approval, we commenced the manufacturing of the staircase in three distinct sections. These sections were then transported to the site, where they underwent the following processes:

The installation of the smoked toughened glass balustrade added a touch of sophistication to the staircase. This included:

The staircase has become a prominent feature in the iconic Gherkin building, showcasing the craftsmanship and attention to detail that CDC Engineering brings to every project. This project holds a special place for our team, representing our commitment to excellence and our ability to deliver bespoke engineering solutions in some of the most prestigious locations.

For more information on our projects and services, visit CDC Engineering Projects.

We are now accepting new enquiries and projects. If you have any bespoke metalwork needs, please do not hesitate to reach out. We would be delighted to discuss how we can bring your vision to life.

MCM. vision for Aldgate House was to create a new image and facilities that would appeal to both creative and corporate occupiers.

Aldgate House has undergone significant refurbishment and CDC Engineering team have been assigned to engineer design,manufacture and fit copper entrance cladding and copper reception desk.

Bespoke copper feature reception desk has been manufactured in our factory that has geometric triangle bends representing contemporary style designers were aiming to achieve. We delivered to the site to fit when the oak black worktop has been fitted to complete the look.

CDC Engineering Completes FCU Cover Project at Belgravia House, Horseferry Road

At CDC Engineering, we take pride in our ability to deliver precise and high-quality bespoke metalwork solutions. Our recent project at Belgravia House, a Grade 2 office building located on Horseferry Road in the heart of Westminster, exemplifies our commitment to excellence in the construction industry. Subcontracted by Woodhouse Workspace, we were tasked with the manufacture and installation of white powder-coated Fan Coil Unit (FCU) covers as part of the building’s full refurbishment and remodeling.

(more…)The refurbishment project at Fleet Place House in Farringdon, City of London, marks a significant upgrade to this landmark office building, enhancing its appeal to both existing and potential tenants and landlords. With a focus on modernisation and longevity, the project aimed to revitalize key areas of the building while also improving its accessibility and contemporary industrial aesthetics.

One of the key challenges faced by the main contractor, OD Group, during the pre-planning phase was the building’s unique position, forming an overpass above a main thoroughfare from the nearby station. This necessitated special permits from TFL for works in and around the building, ensuring compliance and safety amidst the bustling urban environment.

As a subcontractor for the project, our role at CDC Engineering & Fabrication Ltd involved the design, manufacture, and installation of a suspended exterior ceiling beneath the public thoroughfare. This intricate process required meticulous planning and execution, as the busy pedestrian area posed logistical challenges. We systematically dismantled the existing ceiling tiles, manufactured new tiles with perforations to accommodate the new lighting design, and expertly installed them in the bustling public space.

In addition to the exterior ceiling, we were tasked with fabricating contemporary industrial feature signage for the ground floor of Fleet Place House. Crafted from mild steel and finished with a sleek black powder coating, these signs add a modern touch to the building’s entrance, contributing to its refreshed aesthetic.

Overall, the Fleet Place House refurbishment project represents a successful collaboration between contractors, subcontractors, and stakeholders, resulting in a rejuvenated office building that is both visually striking and functional.

Revitalising History: CDC Engineering & Fabrication Ltd’s Contribution to Arthur Stanley House

Situated within the esteemed Charlotte Street conservation area, Arthur Stanley House stands as a beacon of revitalization in the heart of Fitzrovia, central London. Once a decaying 1960s block, this iconic building has undergone a remarkable transformation, thanks to the visionary efforts of ALLFORD HALL MONAGHAN MORRIS architects. Originally designed by TP Bennett Architects as part of the Middlesex Hospital estate, the building opened its doors in 1965, serving as a specialized center for physiotherapy.

Architectural Reimagination

The redevelopment of Arthur Stanley House into a mixed-use office and residential unit marks a significant milestone in the ongoing evolution of Fitzrovia. ALLFORD HALL MONAGHAN MORRIS architects reimagined the former hospital building, breathing new life into its aging façade while preserving its historic significance. The refurbishment project encompassed the transformation of the existing 8-storey structure, blending modern functionality with timeless architectural elegance.

Craftsmanship Unveiled

As subcontractors entrusted with a pivotal role in the redevelopment of Arthur Stanley House, CDC Engineering & Fabrication Ltd took the opportunity to contribute to this iconic project. Working closely with 4K Contracts Ltd, we were tasked with designing, manufacturing, and installing an 8-floor balustrade and oak handrail, adding a touch of sophistication to the building’s interior.

Precision in Process

The journey began at our factory in Essex, where skilled craftsmen meticulously crafted sections of the balustrade from mild steel, ensuring both durability and aesthetic appeal. Each component was carefully powder-coated to enhance its resilience against the elements while maintaining its sleek finish. Meanwhile, our team of artisans handcrafted solid timber smooth oak handrails, seamlessly blending tradition with modernity.

On-Site Excellence

With precision-engineered components in hand, CDC Engineering & Fabrication Ltd’s site team embarked on the final phase of the project: installation at Arthur Stanley House. Leveraging years of expertise and a commitment to excellence, our team delivered and precisely welded each component, ensuring a seamless fit and flawless finish. The result is a stunning amalgamation of architectural innovation and masterful craftsmanship, elevating the interior ambiance of Arthur Stanley House to new heights.

Conclusion

The redevelopment of Arthur Stanley House stands as a testament to the transformative power of architectural vision and skilled craftsmanship. At CDC Engineering & Fabrication Ltd, we are honored to have played a role in bringing this landmark project to life. Our commitment to excellence and dedication to quality shines through in every aspect of the balustrade and oak handrail installation, leaving a lasting impression on all who enter Arthur Stanley House.

To learn more about our projects and services, visit our website or contact us directly.

CDC Engineering & Fabrication Ltd’s Metalwork Masterpiece at Aldwych House

At CDC Engineering & Fabrication Ltd, we pride ourselves on our commitment to excellence in architectural metalwork. Recently, we had the privilege to collaborate with Virtus Contracts on a prestigious project at Aldwych House in Reading. As specialists in bespoke metalwork, we were tasked to manufacture and install blackened steel wall panels in the main reception, along with external main entrance soffit cladding and internal lift surrounds.

Exquisite Craftsmanship

From the outset, our team at CDC Engineering & Fabrication Ltd approached the project at Aldwych House with meticulous attention to detail and precision. Each component was carefully crafted to seamlessly integrate with the building’s aesthetic while ensuring functionality and durability. Our expertise in architectural metalwork allowed us to deliver exceptional results that exceeded expectations.

One of the hallmarks of our work at CDC Engineering & Fabrication Ltd is our ability to tailor solutions to meet the unique needs of each project. For Aldwych House, we worked closely with Virtus Contracts to understand their vision and specifications, ensuring that our metalwork complemented the overall design concept seamlessly.

The installation of blackened steel wall panels with flutted glass partitions in the main reception of Aldwych House has transformed the space, adding a touch of sophistication and modernity. We have worked with the designers to achieve this rustic but elegant blackened steel finish that satisfied our client.

At CDC Engineering & Fabrication Ltd, we are dedicated to delivering exceptional quality and craftsmanship in every project we undertake. Our collaboration with Virtus Contracts on the Aldwych House project exemplifies our commitment to excellence in architectural metalwork. From concept to completion, we strive to exceed expectations and elevate the built environment with our bespoke solutions.

To learn more about our projects and services, visit our website or contact us directly.