Since the Mondrian Shoreditch London hotel’s acquisition by the Reuben Brothers in 2020, the property has undergone a dramatic renovation, becoming a destination where contemporary luxury meets the artistic energy of Shoreditch.

Throughout this project, CDC Engineering worked closely with Goddard Littlefair design team to manufacture and install a variety of architectural metalwork features. Copper played a central role in the design narrative, and our ability to create bespoke finishes entirely in house allowed us to deliver the precise aesthetic and atmosphere envisioned by the designers.

The interior concept relied heavily on copper’s ability to bring warmth, brightness, and a playful sense of reflection into the spaces. To achieve this, each area of the hotel required a distinct copper finish, ranging from deep, aged surfaces to vibrant polished tones. Because CDC Engineering develops all finishes internally—including acid etching, patination, antiquing, and protective lacquering—we were able to respond directly to the designers’ requirements, refining tones, textures and reflectivity until the exact look was achieved.

With many years of experience working with metal finishes, our workshop is designed to give architects and designers full creative control. Every finish can be prototyped, adjusted, and perfected on site, ensuring consistency and high performance in the final installation.

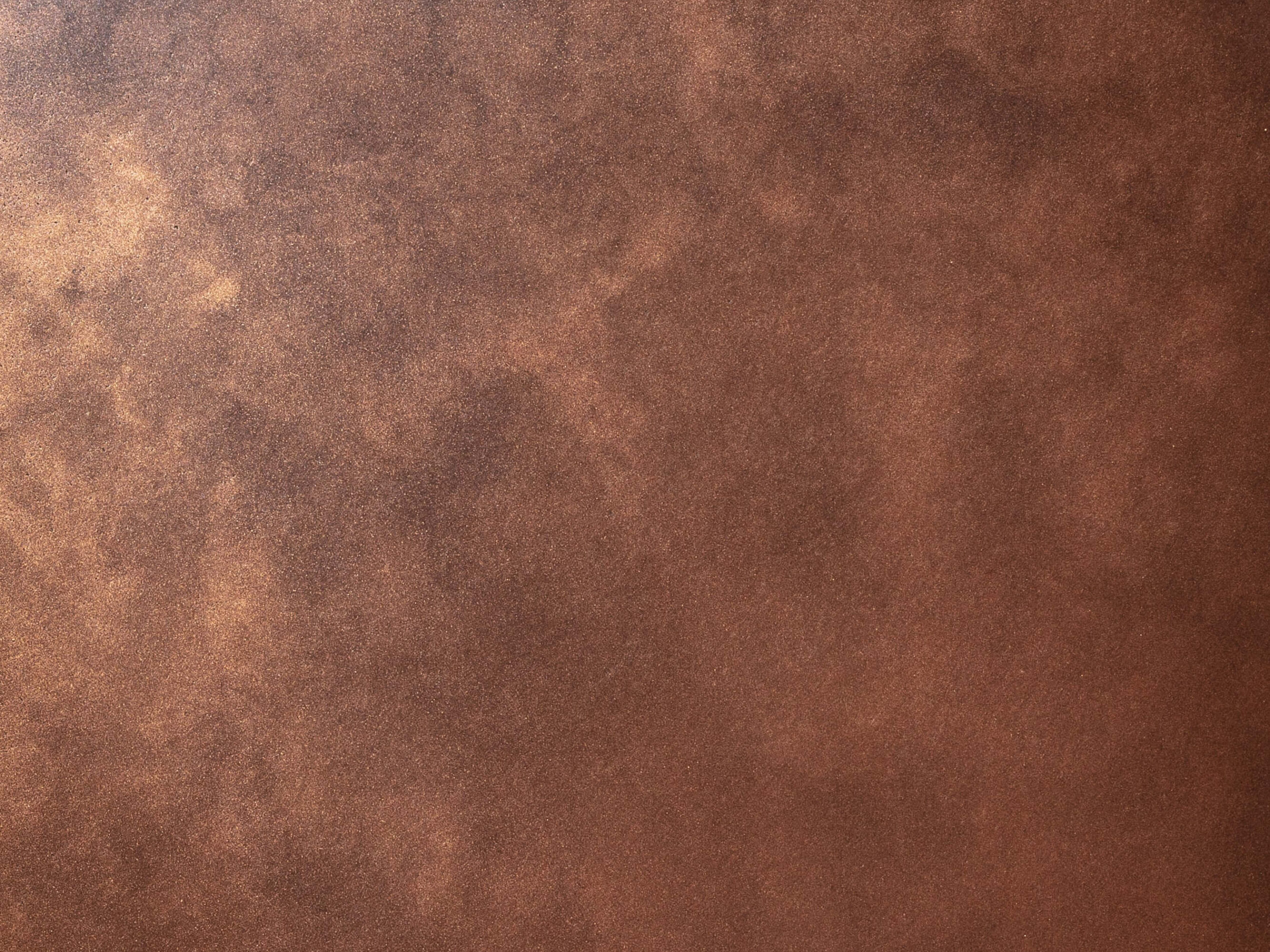

Upon entering the hotel, guests are greeted by an installation of aged antique mottled copper that forms the backdrop to the reception desk. This finish continues around the lift surrounds, creating a cohesive and atmospheric first impression. The designers asked for a darker, richer tone that would anchor the space, while still offering a gentle reflective quality. By applying a lacquered topcoat, we were able to introduce a subtle play of light across the surface, enhancing the lobby’s warm and welcoming feel.

Acid etching is a process when material, in this case copper, is cut using specifically formulated acid. Acid etching metal is a non-contact process. The acid dissolves the metal sections around the part features that are not coated with a photoresist laminate. The process avoids any contact with hard tooling that is often used in conventional methods such as stamping and CNC machining. For this reason, etching metal is favored over the other processes when the absence of burrs is critical to the part’s requirements.

The mottled finish itself evokes the appearance of naturally aged copper, with its deep base colour and delicate variations of lighter tones. This character is achieved through a controlled antiquing method, where the metal is aged and then refined by hand to reveal the soft contrasts that give it depth and authenticity. The result is a surface that feels both timeless and tactile, with an artisanal quality that avoids the uniformity of mechanically polished metals.

In contrast to the reception space, the restaurant required copper elements that would bring brightness and vibrancy to the interior. CDC Engineering manufactured polished copper wall cladding, a copper rod bar gantry, and a polished footrest for the bar area.

The gantry, featuring a globe lamp suspended at its centre, became one of the key focal points of the restaurant. The highly polished copper amplified the light from the globe, producing a lively and dynamic interaction between material and illumination. Achieving this level of clarity and reflectivity involved precise fabrication and an intensive polishing process, ensuring that the copper surfaces remained seamless and visually fluid.

A polished copper finish is created by first smoothing the metal through a series of sanding or abrasive stages, gradually refining the surface until all imperfections are removed. The copper is then mechanically polished using specialised wheels and compounds, which build up the bright, reflective shine. Once the desired clarity is reached, the surface is cleaned and typically sealed with a protective lacquer or wax to preserve its brilliance and prevent oxidation. The result is a smooth, mirror-like finish that enhances copper’s natural warmth and elegance.

One of the most technically demanding features of the project was the bright antique copper bar in the lounge area. Manufactured entirely at our factory, this installation includes a curved ceiling element that blends gracefully into the bar cladding below. Creating a finish that remained consistent across these flowing surfaces required careful control of both the fabrication and finishing processes.

Our team developed a vivid antique copper tone with an orange warmth that complemented the lighting and overall design scheme. The reflective quality of the finish added energy to the room, enhancing the sense of movement created by the curved geometry. The bar was finished in the same material, ensuring continuity throughout the space and reinforcing the sense of craftsmanship that runs through the hotel’s interior.

The Mondrian Shoreditch project showcases how impactful bespoke metalwork can be when design ambition is supported by technical expertise. With all finishing carried out under one roof, CDC Engineering is able to guide designers from concept to completion with a level of control and consistency that is essential in complex hospitality environments. Each copper element in the project reflects a close collaboration between design vision and material capability, resulting in interiors that feel rich, expressive, and beautifully crafted.

Get in touch with our team to discuss your project:

T: 01702 294449