At CDC Engineering and Alpine Fabrication, we specialise in producing bespoke metalwork pieces with unique metal finishes. We are experts in colouring, bronzing, and patinating sheet metals based on client specifications, creating unique surface finishes for a variety of buildings’ features, including bar and desk fronts, lifts, internal wall coverings, decorative panels, signage, wall cladding, architectural architraves, fan coil unit (FCU) covers and much more.

Patination is the process of developing a texture upon the surface of a metal using chemicals. It involves creating a chemical reaction that forms a coloured oxide on the surface of the metal. Unlike some competing fabrication companies, we do this in-house to provide our clients with unique finishes that are tailored to their properties. Working with metals such as copper, brass, and mild steel, we create a wide range of patinated and bespoke finishes.

Our patination process involves acid etching, a technique we use to create intricate designs on metal surfaces. We use a variety of our own blend chemicals to cut into metal surfaces and produce detailed patterns and textures. No heat or mechanical force is applied to the metal during the etching process, meaning the material’s properties are not compromised and can be safely used in construction.

We also apply specific chemicals to metals that accelerate the natural ageing process and create an antique appearance often used by architects and interior designers. The resulting finish of the metal will depend on the duration of time that the chemical is left on the metal’s surface.

We worked alongside Box 9 Design to achieve the desired vision of the old Victorian railway station setting, The Rail House Café, creating an intimate restaurant and bar based in London. We manufactured the ceilings, bars, and other architectural features using our acid etching technique to create an antique aesthetic reminiscent of past railway stations.

We manufactured the ornate staircase that leads customers up to the bar on the first floor.

We used patination to create this antique staircase which complements the rustic design of the property. All the metalwork we created was patinated based on the restaurant’s appearance and the information provided by the architect.

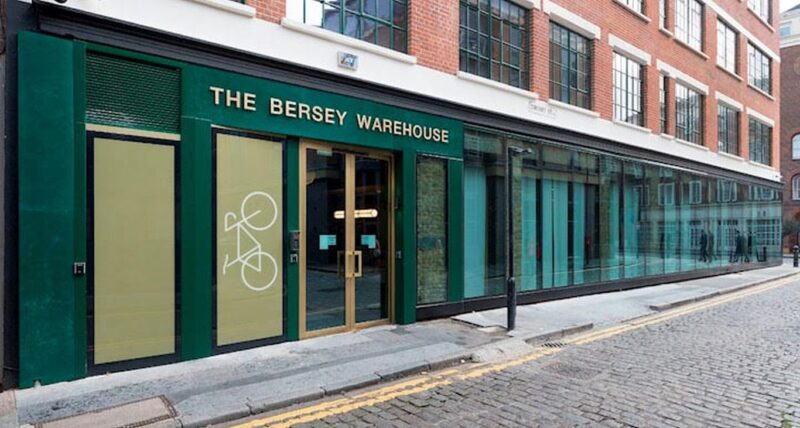

The Bersey Warehouse is a commercial building that was acquired by Aviva and refurbished by Collins and Architects Buckley Grey Yeoman.

Built between 1913 and 1939, this old building was transformed into a modern space that retains its character, enhanced with our patinated metal features.

We manufactured copper verde facades, external window frames, signage, and cladding that suited the art deco feel of the building.

We used a bronzing technique to create a smooth textured finish on the lifts that complements the architect’s visual requirements. We also supplied the building with FCU covers that were specifically designed to suit the property while reducing vibration and noise.

We were contracted to supply bespoke FCU covers to the Holborn Gate office block. We liaised with the architects to understand the desired finish and overall décor of the building. We then created a prototype of the FCU cover and samples of the patinated metal finish to ensure the client was satisfied before we started the manufacturing process.

We manufactured the hot rolled, black lacquered reception desk and wall features in the front house within the building.

We also internally and externally cladded the entrance porticos on the north and south elevations, which are cladded in our acid etched, dark bronze, earth finish.

At CDC Engineering, we explore traditional techniques of patination such as acid etching and immersion. We also experiment with our in-house recipes to deliver unique finishes. Using a variety of metals, we specialise in forming unique textures, patterns and finishes that we have developed through decades of industry experience. We supply our clients with samples to ensure that they approve the bespoke finish before we move to the production phase. When we work on new projects, we can use our extensive range of decorative aged metal finishes to create designers’ and architects’ required effects. We can demonstrate our range of finishes by sending samples directly to architects and designers.

Our in-house capabilities ensure that our skilled craftsmen have complete control of the process and produce bespoke finishes that exceed your expectations. Our team of experts will conduct site visits to understand your requirements and create bespoke metal finishes that complement your property.

If you would like more information about our projects and samples, please get in touch with our team.