MCM. vision for Aldgate House was to create a new image and facilities that would appeal to both creative and corporate occupiers.

Aldgate House has undergone significant refurbishment and CDC Engineering team have been assigned to engineer design,manufacture and fit copper entrance cladding and copper reception desk.

Bespoke copper feature reception desk has been manufactured in our factory that has geometric triangle bends representing contemporary style designers were aiming to achieve. We delivered to the site to fit when the oak black worktop has been fitted to complete the look.

CDC Engineering Completes FCU Cover Project at Belgravia House, Horseferry Road

At CDC Engineering, we take pride in our ability to deliver precise and high-quality bespoke metalwork solutions. Our recent project at Belgravia House, a Grade 2 office building located on Horseferry Road in the heart of Westminster, exemplifies our commitment to excellence in the construction industry. Subcontracted by Woodhouse Workspace, we were tasked with the manufacture and installation of white powder-coated Fan Coil Unit (FCU) covers as part of the building’s full refurbishment and remodeling.

(more…)The refurbishment project at Fleet Place House in Farringdon, City of London, marks a significant upgrade to this landmark office building, enhancing its appeal to both existing and potential tenants and landlords. With a focus on modernisation and longevity, the project aimed to revitalize key areas of the building while also improving its accessibility and contemporary industrial aesthetics.

One of the key challenges faced by the main contractor, OD Group, during the pre-planning phase was the building’s unique position, forming an overpass above a main thoroughfare from the nearby station. This necessitated special permits from TFL for works in and around the building, ensuring compliance and safety amidst the bustling urban environment.

As a subcontractor for the project, our role at CDC Engineering & Fabrication Ltd involved the design, manufacture, and installation of a suspended exterior ceiling beneath the public thoroughfare. This intricate process required meticulous planning and execution, as the busy pedestrian area posed logistical challenges. We systematically dismantled the existing ceiling tiles, manufactured new tiles with perforations to accommodate the new lighting design, and expertly installed them in the bustling public space.

In addition to the exterior ceiling, we were tasked with fabricating contemporary industrial feature signage for the ground floor of Fleet Place House. Crafted from mild steel and finished with a sleek black powder coating, these signs add a modern touch to the building’s entrance, contributing to its refreshed aesthetic.

Overall, the Fleet Place House refurbishment project represents a successful collaboration between contractors, subcontractors, and stakeholders, resulting in a rejuvenated office building that is both visually striking and functional.

Revitalising History: CDC Engineering & Fabrication Ltd’s Contribution to Arthur Stanley House

Situated within the esteemed Charlotte Street conservation area, Arthur Stanley House stands as a beacon of revitalization in the heart of Fitzrovia, central London. Once a decaying 1960s block, this iconic building has undergone a remarkable transformation, thanks to the visionary efforts of ALLFORD HALL MONAGHAN MORRIS architects. Originally designed by TP Bennett Architects as part of the Middlesex Hospital estate, the building opened its doors in 1965, serving as a specialized center for physiotherapy.

Architectural Reimagination

The redevelopment of Arthur Stanley House into a mixed-use office and residential unit marks a significant milestone in the ongoing evolution of Fitzrovia. ALLFORD HALL MONAGHAN MORRIS architects reimagined the former hospital building, breathing new life into its aging façade while preserving its historic significance. The refurbishment project encompassed the transformation of the existing 8-storey structure, blending modern functionality with timeless architectural elegance.

Craftsmanship Unveiled

As subcontractors entrusted with a pivotal role in the redevelopment of Arthur Stanley House, CDC Engineering & Fabrication Ltd took the opportunity to contribute to this iconic project. Working closely with 4K Contracts Ltd, we were tasked with designing, manufacturing, and installing an 8-floor balustrade and oak handrail, adding a touch of sophistication to the building’s interior.

Precision in Process

The journey began at our factory in Essex, where skilled craftsmen meticulously crafted sections of the balustrade from mild steel, ensuring both durability and aesthetic appeal. Each component was carefully powder-coated to enhance its resilience against the elements while maintaining its sleek finish. Meanwhile, our team of artisans handcrafted solid timber smooth oak handrails, seamlessly blending tradition with modernity.

On-Site Excellence

With precision-engineered components in hand, CDC Engineering & Fabrication Ltd’s site team embarked on the final phase of the project: installation at Arthur Stanley House. Leveraging years of expertise and a commitment to excellence, our team delivered and precisely welded each component, ensuring a seamless fit and flawless finish. The result is a stunning amalgamation of architectural innovation and masterful craftsmanship, elevating the interior ambiance of Arthur Stanley House to new heights.

Conclusion

The redevelopment of Arthur Stanley House stands as a testament to the transformative power of architectural vision and skilled craftsmanship. At CDC Engineering & Fabrication Ltd, we are honored to have played a role in bringing this landmark project to life. Our commitment to excellence and dedication to quality shines through in every aspect of the balustrade and oak handrail installation, leaving a lasting impression on all who enter Arthur Stanley House.

To learn more about our projects and services, visit our website or contact us directly.

CDC Engineering & Fabrication Ltd’s Metalwork Masterpiece at Aldwych House

At CDC Engineering & Fabrication Ltd, we pride ourselves on our commitment to excellence in architectural metalwork. Recently, we had the privilege to collaborate with Virtus Contracts on a prestigious project at Aldwych House in Reading. As specialists in bespoke metalwork, we were tasked to manufacture and install blackened steel wall panels in the main reception, along with external main entrance soffit cladding and internal lift surrounds.

Exquisite Craftsmanship

From the outset, our team at CDC Engineering & Fabrication Ltd approached the project at Aldwych House with meticulous attention to detail and precision. Each component was carefully crafted to seamlessly integrate with the building’s aesthetic while ensuring functionality and durability. Our expertise in architectural metalwork allowed us to deliver exceptional results that exceeded expectations.

One of the hallmarks of our work at CDC Engineering & Fabrication Ltd is our ability to tailor solutions to meet the unique needs of each project. For Aldwych House, we worked closely with Virtus Contracts to understand their vision and specifications, ensuring that our metalwork complemented the overall design concept seamlessly.

The installation of blackened steel wall panels with flutted glass partitions in the main reception of Aldwych House has transformed the space, adding a touch of sophistication and modernity. We have worked with the designers to achieve this rustic but elegant blackened steel finish that satisfied our client.

At CDC Engineering & Fabrication Ltd, we are dedicated to delivering exceptional quality and craftsmanship in every project we undertake. Our collaboration with Virtus Contracts on the Aldwych House project exemplifies our commitment to excellence in architectural metalwork. From concept to completion, we strive to exceed expectations and elevate the built environment with our bespoke solutions.

To learn more about our projects and services, visit our website or contact us directly.

Mastering Elegance: CDC Engineering’s Contribution to The Post Building Project

Subtitle: A Tale of Contemporary Spiral Staircases, Precision, and Architectural Brilliance

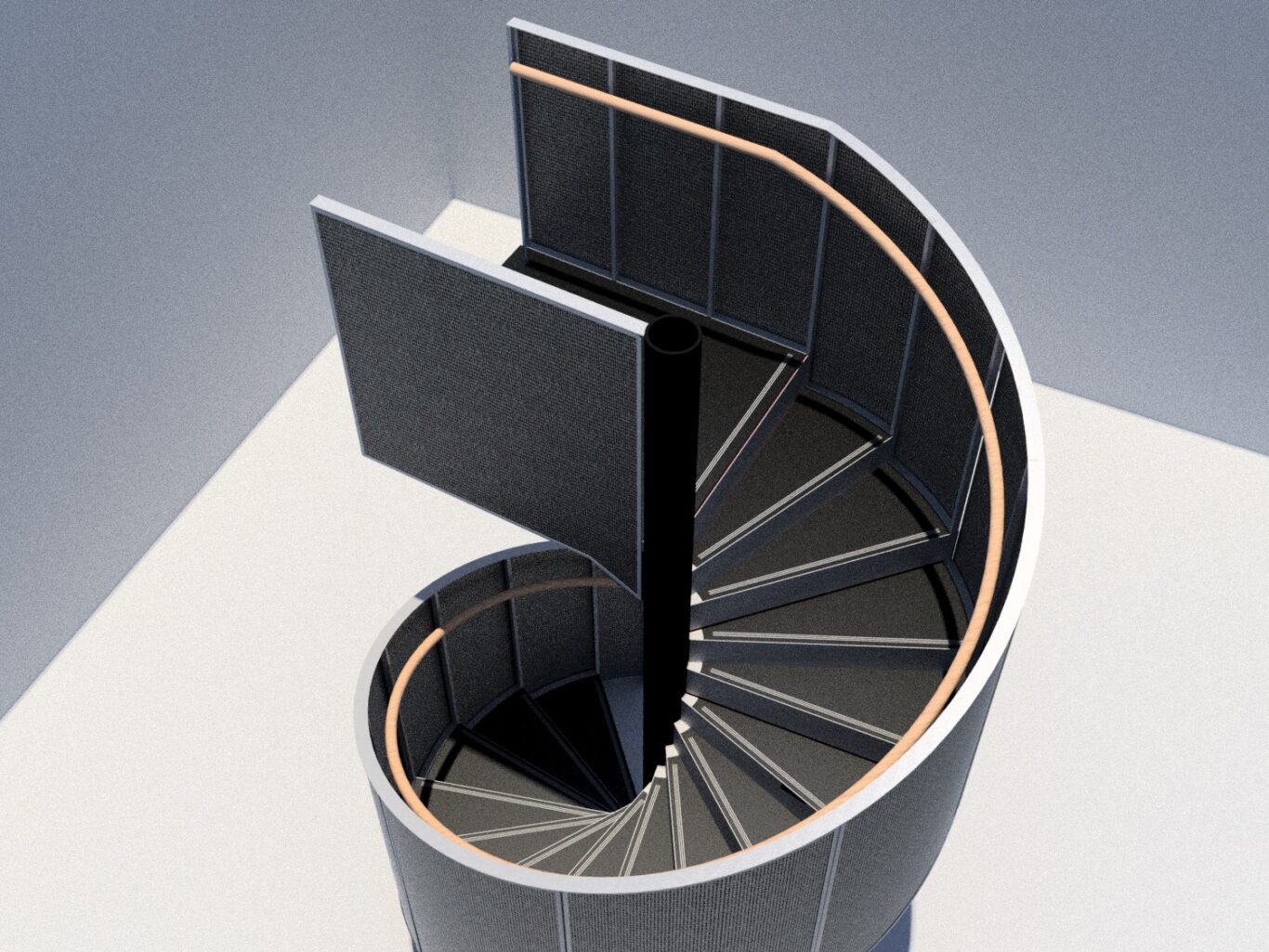

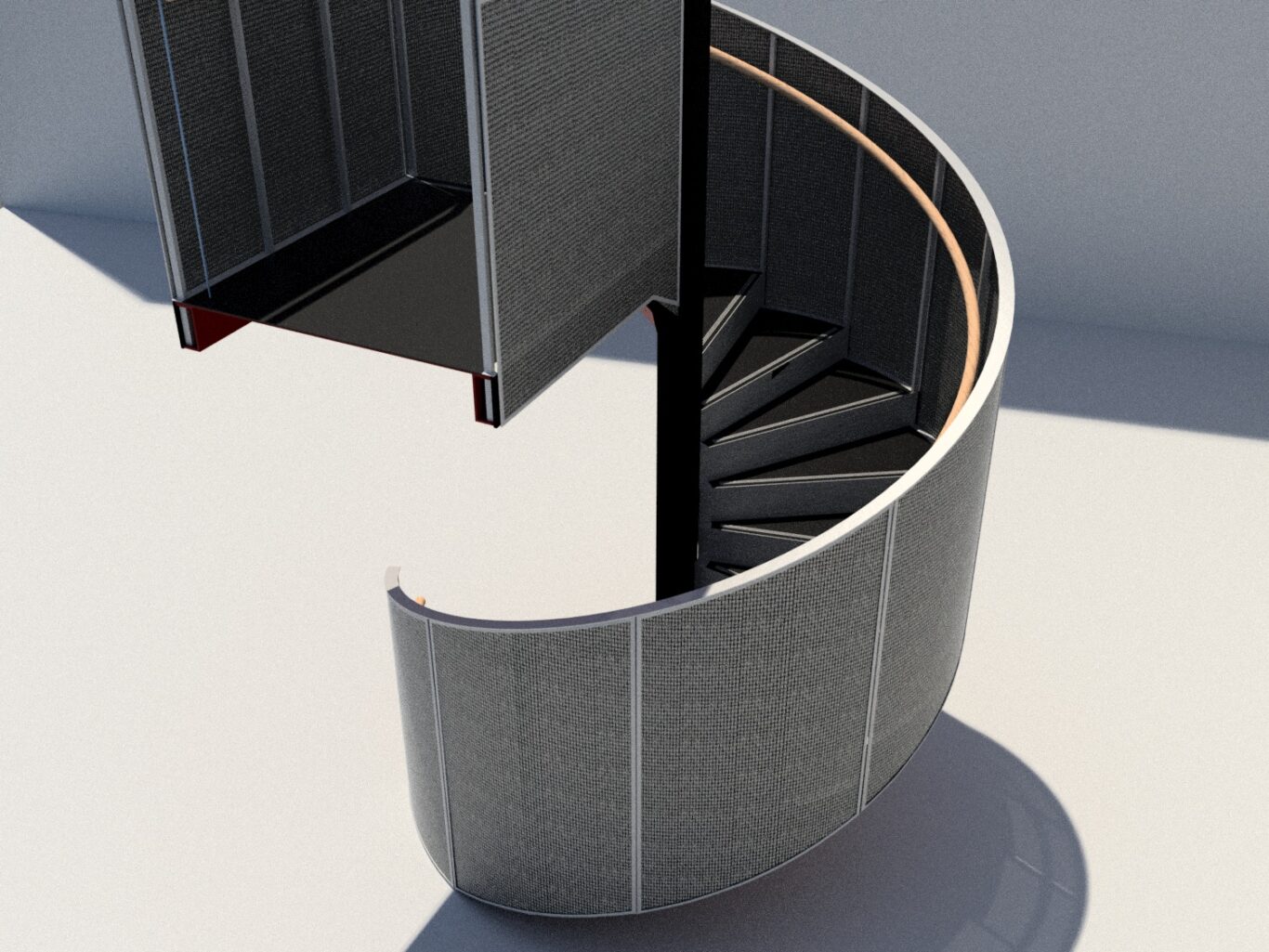

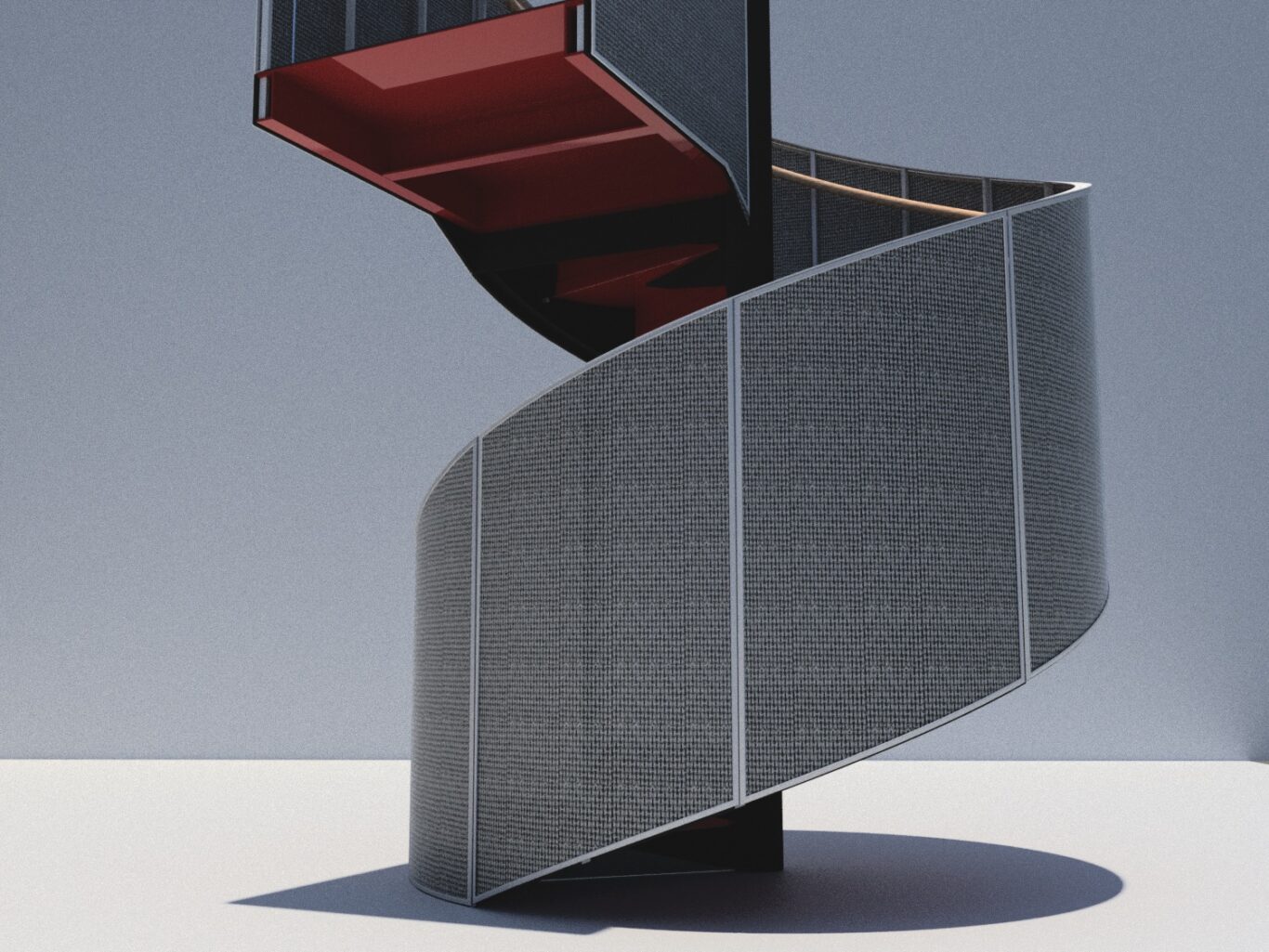

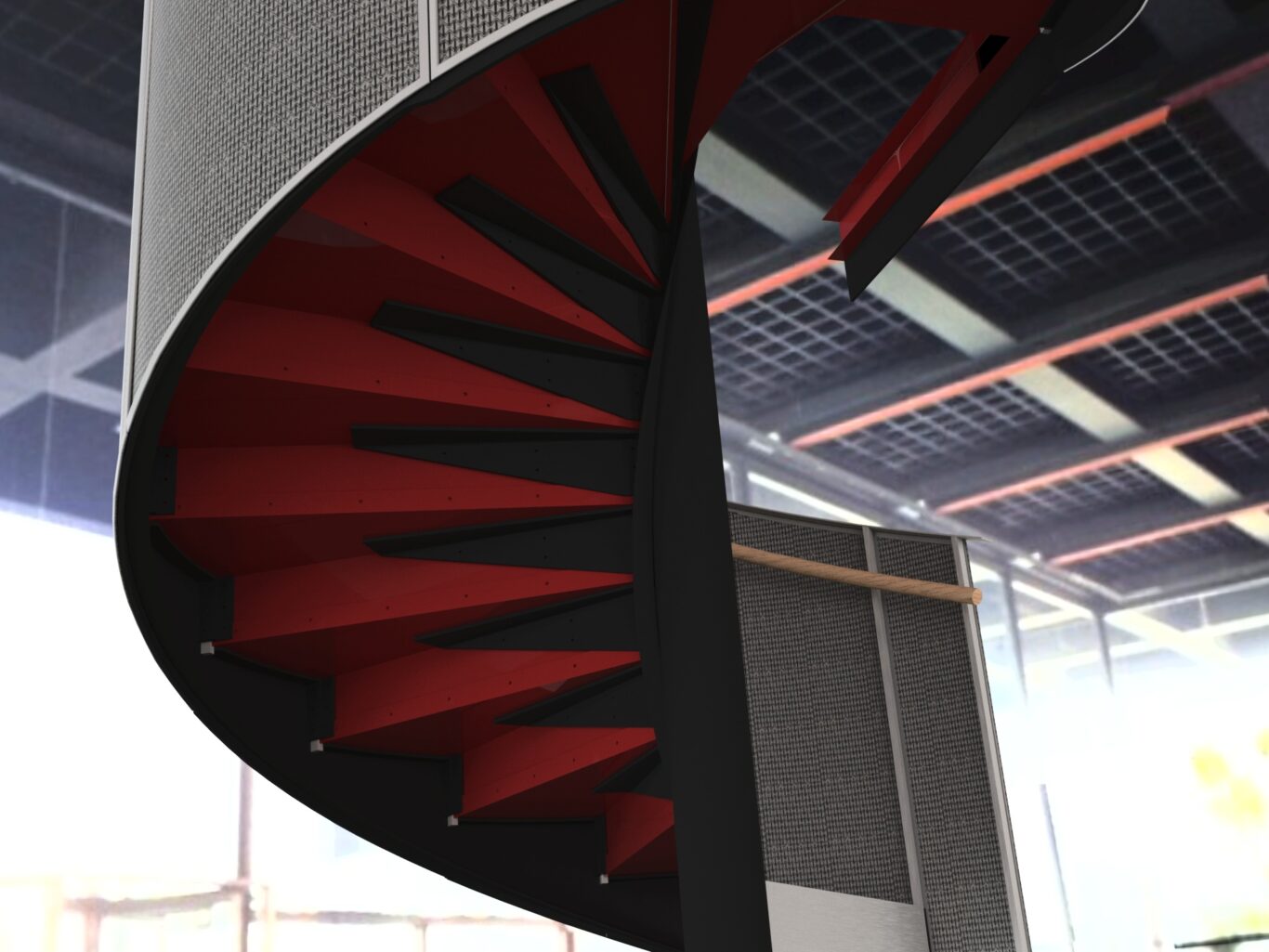

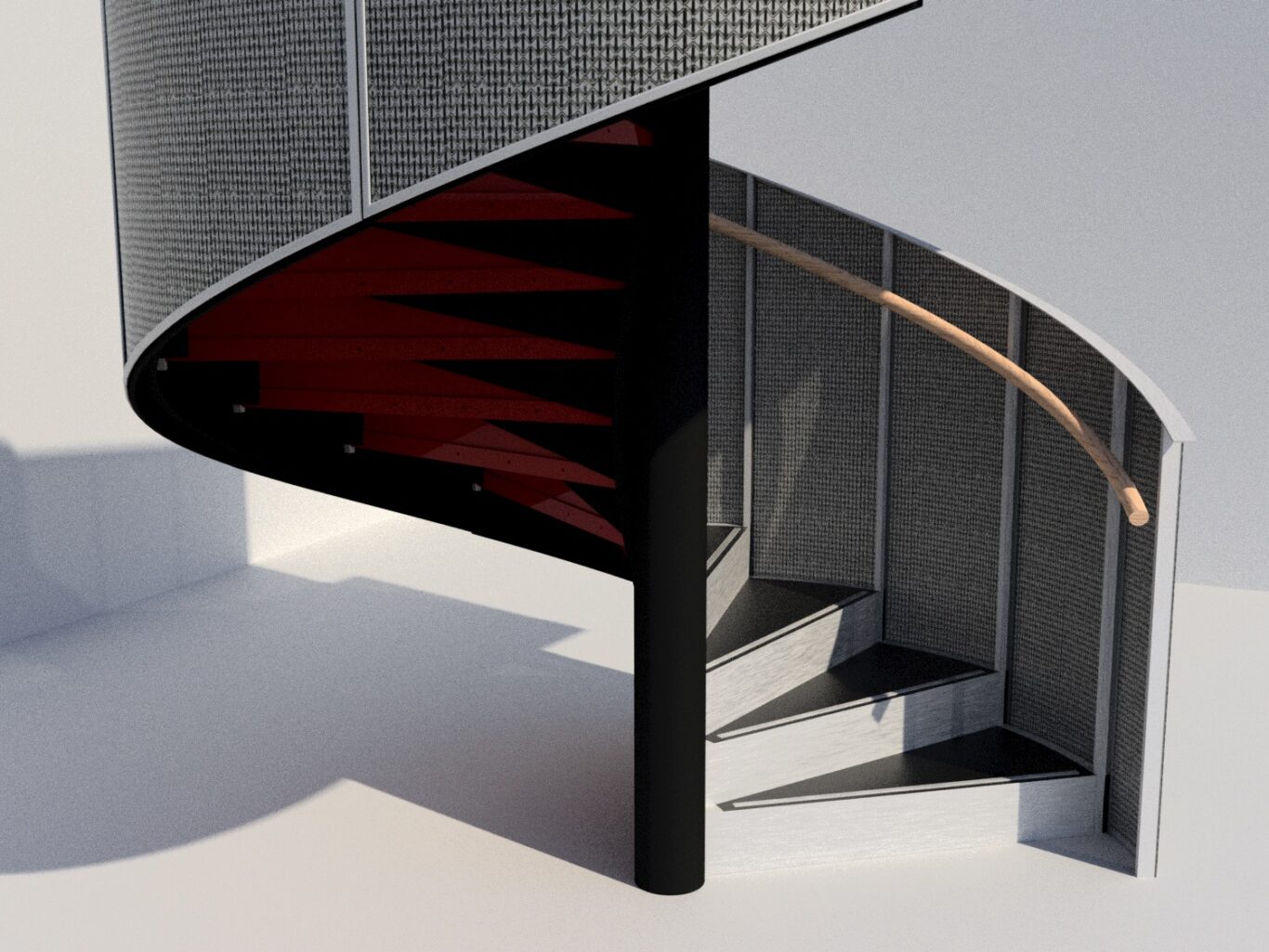

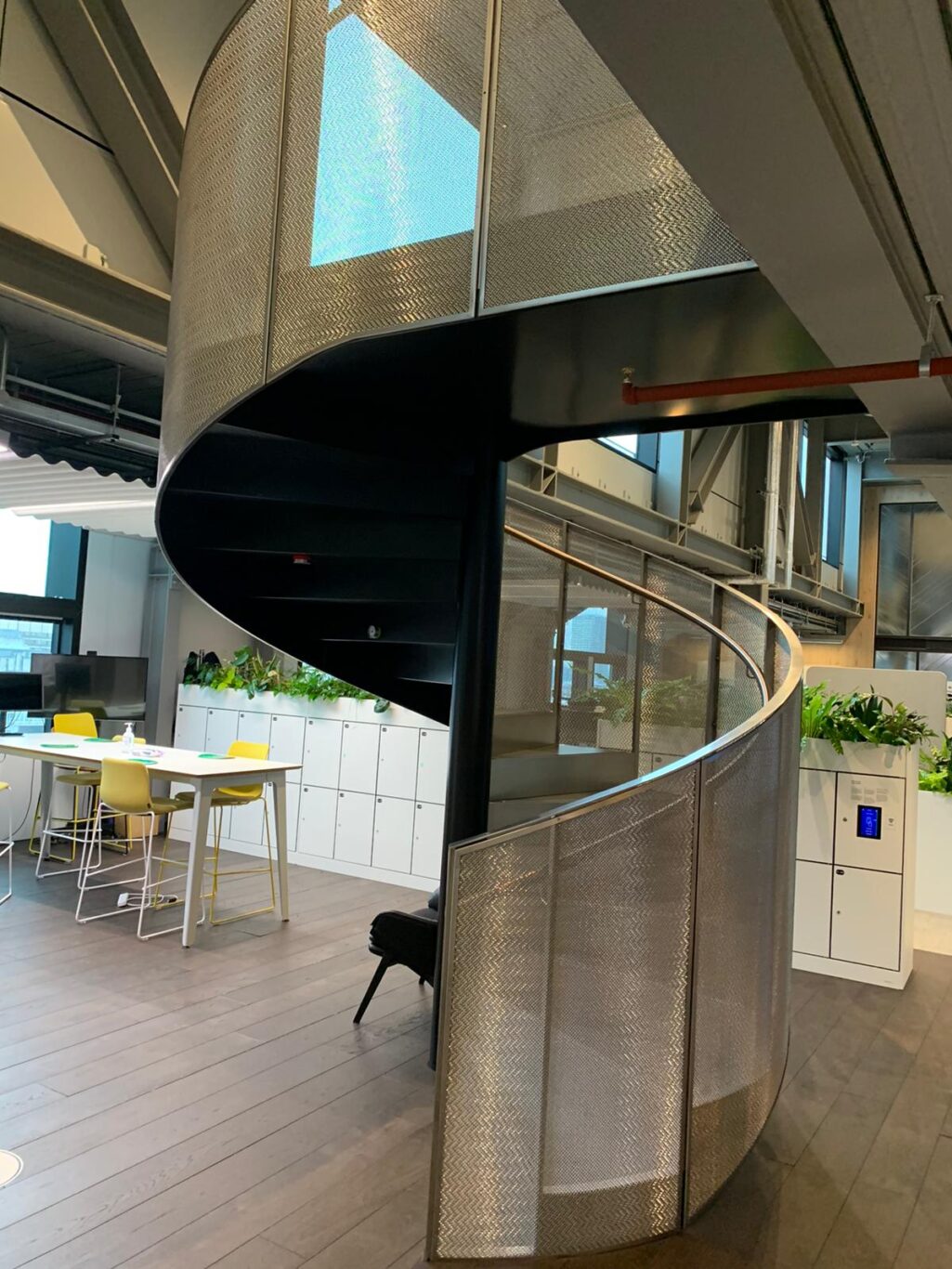

CDC Engineering had the privilege of collaborating with BW Interiors and the visionary architects at Allford Hall Monaghan Morris to bring to life the breathtaking spiral staircases at The Post Building.

The Post Building Project: A Fusion of Art and Architecture

Main Contractor: BW Interiors | Main Architect: Allford Hall Monaghan Morris

Duration: 24 Weeks

Unveiling Architectural Marvels: Contemporary Spiral Staircases

The heart of The Post Building lies on the 8th floor, where CDC Engineering’s craftsmanship took center stage. Our task? Designing, manufacturing, and fitting not one but two contemporary style spiral staircases, each a testament to precision and aesthetic brilliance.

Design Elements:

Symmetry in Motion: Clockwise and Anticlockwise Spirals

The uniqueness of the project lies not only in the contemporary design but also in the thoughtful placement of two spiral staircases, mirroring each other on the 8th floor. One staircase gracefully ascends clockwise, while its counterpart dances in the opposite direction, creating a stunning visual symphony.

Collaboration in Action: CDC Engineering, BW Interiors, and AHMM

24 Weeks of Synergy

The successful completion of The Post Building project was made possible through a collaborative effort that spanned 24 weeks. CDC Engineering worked hand-in-hand with BW Interiors and Allford Hall Monaghan Morris, ensuring that every detail of the spiral staircases was meticulously crafted to perfection.

Behind the Scenes: Crafting Excellence

Precision in Manufacturing:

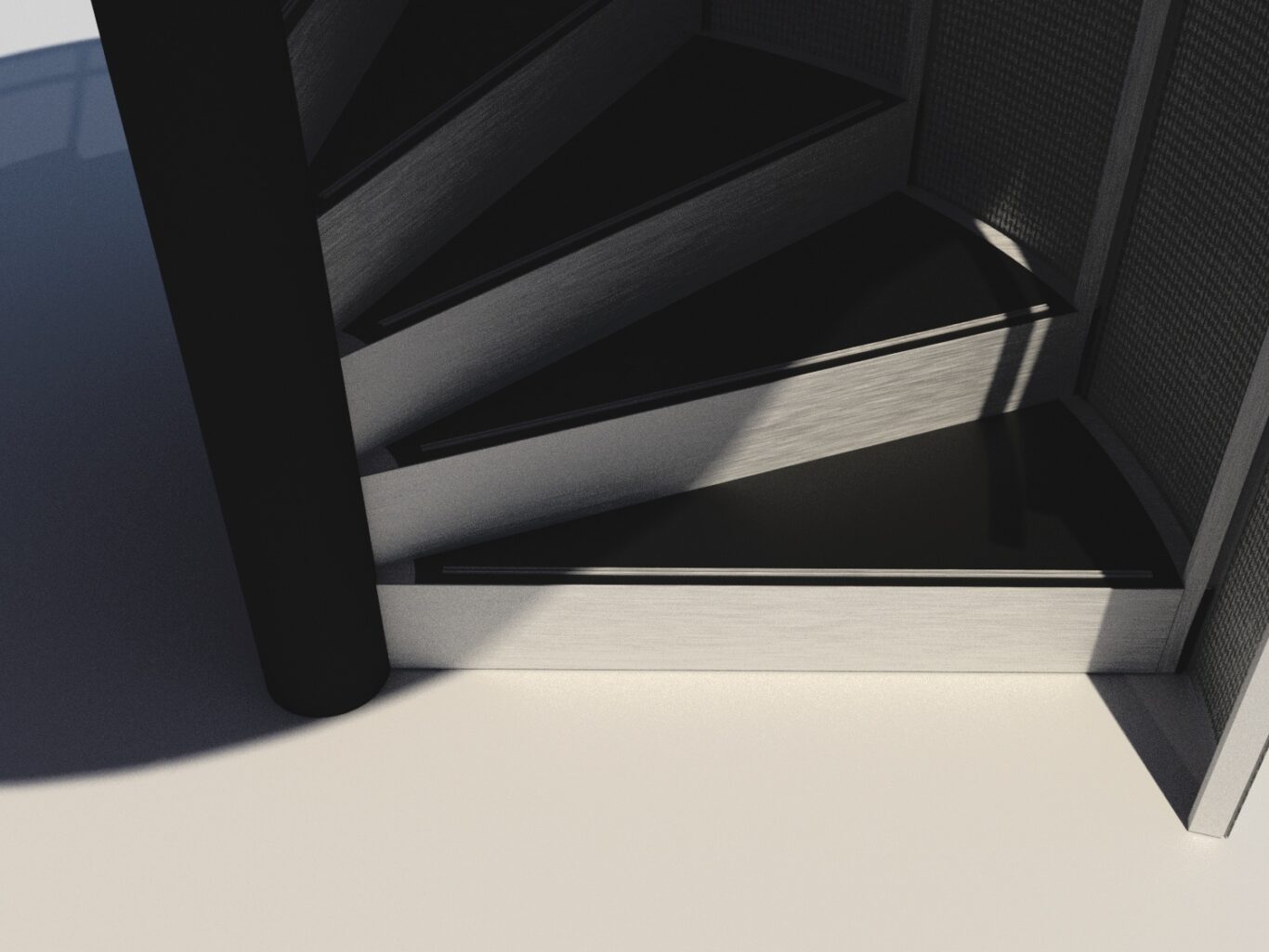

Our skilled craftsmen at CDC Engineering brought the architectural vision to life. From precision cutting to expert welding, every step was executed with a commitment to excellence.

On-Site Fittings:

Collaborating closely with BW Interiors, our team seamlessly integrated the spiral staircases into the 8th-floor space, ensuring a flawless fit that complemented the overall design.

Architectural Harmony:

The collaboration with Allford Hall Monaghan Morris allowed us to understand the architectural nuances of The Post Building. The result? Spiral staircases that not only serve their functional purpose but also enhance the overall aesthetic appeal.

Elevating Architectural Excellence

At CDC Engineering, we take pride in turning architectural dreams into reality. The Post Building project stands as a testament to our commitment to precision, innovation, and collaboration. As the spiral staircases gracefully welcome inhabitants and visitors alike, we reflect on the artistry and engineering that define CDC Engineering.

CDC Engineering – Elevating Architectural Excellence, One Project at a Time.

AutoCAD drawings prior manufacturing.

Intallation stage on site when all parts become connected.

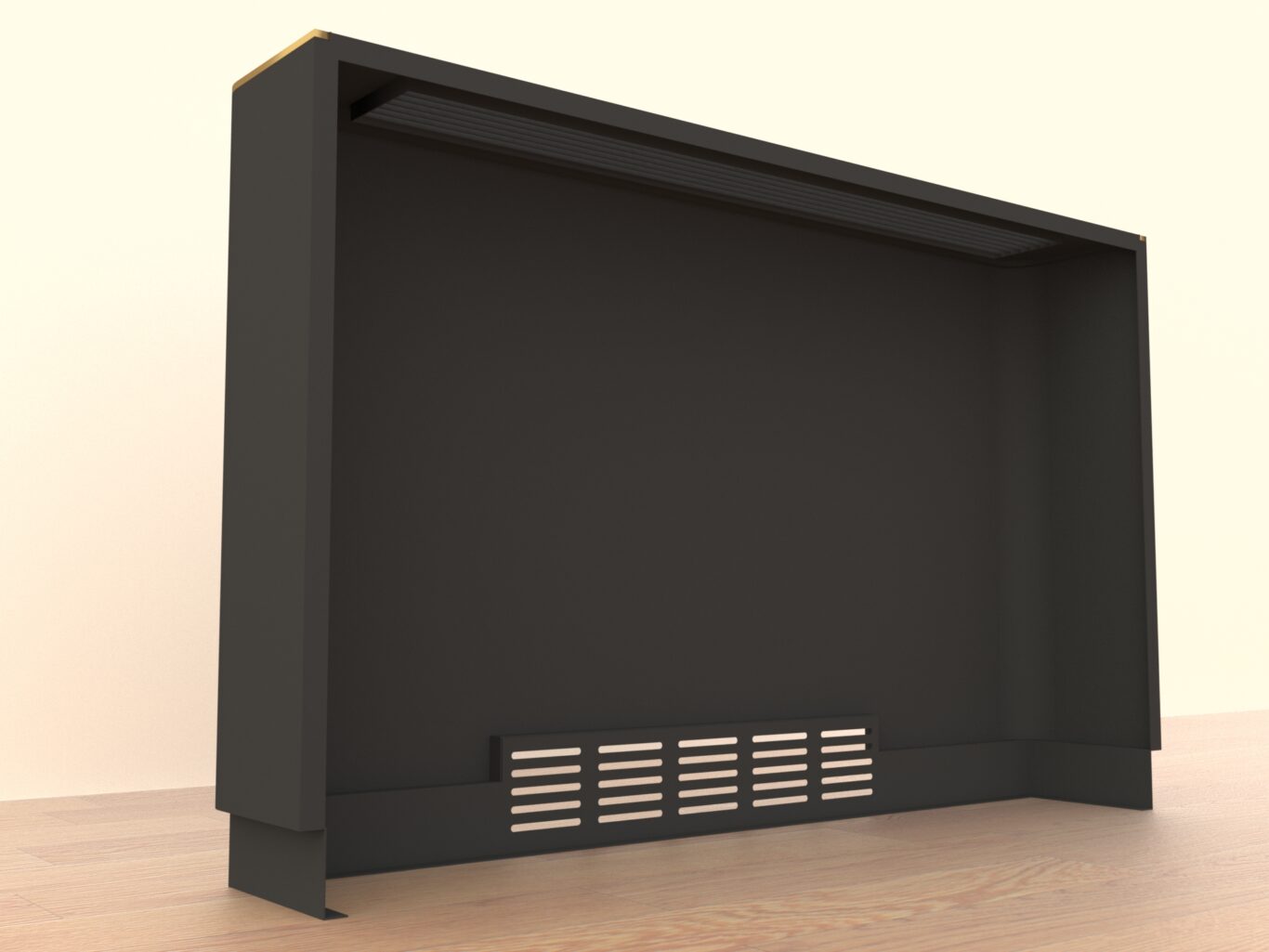

Set in the heart of London, at one of its finest business addresses, is 73-77 Brook Street, developed and managed by Clivedale London. This ground-breaking development offers some 31,500 sq. ft. of flexible commercial space backed by an unmatched range and quality of services.

We have been contracted by JT3 Interiors Ltd to manufacture, supply and fit wall mounted, and 1 freestanding FCU covers keeping the same design that sat over 2 floors. The unique art decco style bespoke FCU covers have been made to an agreed drawing, manufactured from coled rolled mild steel, and finished in a Ral9004 ppc 30% black power coated satin finish as requested by the client. They had angles grilles, internal baffles to maximise the direction of the airflow straight to the grill.

The brass trim feature to top edges meant to compliment the FCU covers, but designers have changed their mind and decided to keep it simple as FCU covers style already was blending in the interior.

FCU enclosures have been fitted outside of office hours to suit the clients’ request. More information about custom made FCU covers can be found on Alpine Fabrication website.

CDC Engineering was contracted to manufacture and install a variety of features within the building, such as the aged copper wall nook in the reception area and the copper cladding to columns. The copper features were acid aged and surface finished in house workshop after manufacturing the panels and before installation.

On the upper floors of the building, the Tea point stations and associated doors were manufactured from birch-faced ply. With exposed joints and polished edges, the tea stations and associated doors were machine cut in our workshop and hand-finished on site.

We also designed and manufactured the back terrace birch and mild steel columns and cladding that feature with its unique design.

Our sister company Alpine Fabrication has been contracted to manufacture and fit FCU covers for Britten Street project. The commercial building located in 60/61 Britten Street, Clerkenwell, London was fully refurbished for new offices. Our team made a 3D scan and completed the survey of the office space and enclosed offices to understand the work required for the project. After the survey, we analysed the data, engineered the designs of the FCU covers, and manufactured the prototype that has been sent to the client for approval.

Alpine team has manufactured two different sizes of FCU covers to accommodate the different unit sizes within the building. The FCU covers were made from one piece of sheet steel, formed with folded side channels to make the covers ridged. This was then combined with a concealed folded air intake on the front face to ensure the cover does not impact the performance of the FCU.

The FCU covers were insulated with Armaflex foam that provides market leading energy conserving properties and soundproofing. Armaflex insulation is designed to mitigate the risk of moisture accumulation and condensation that leads to mold.

The FCU covers were professionally finalised based on the colour and finish that’s been provided by the client. The covers can easily be lifted on and off the wall-mounted rails when maintenance is required.

CityPoint Plaza is an existing open space located adjacent to CityPoint Tower in the City of London. The public realm had become dated and under-used, cluttered with rows of planters, and raised vent shafts, kiosks and staircases making wayfinding difficult. There was minimal seating and a lack of programming in the space to make it desirable for people to use.

Brookfield Properties recently purchased the building, and working with Allies and Morison Architects, the brief was to reimagine the public spaces, vent shafts, kiosks and entry sequence into the building as part of a temporary landscape intervention.

Charles Edward appointed us to engineer, manufacture and install black hot rolled mild steel entrance reception desk on the ground floor, as well as bespoke lift doors, surrounds and trims at the CityPoint Plaza building London. Distinct design reception desk features the contemporary interior and is complimented by the Dynamo’s latest digital art that displayed on a large LED video wall showing custom digital artwork that was curated by acrylicize.

Sub-contracted by Charles Edward we have also manufactured and fitted ground floor lift doors, surrounds and trims. Contemporary design lifts represent our precise work and high quality services.

Beast is a unique fine dining concept from DesignLSM’s long-standing client, the Goodman Restaurant Group. DesignLSM appointed CDC Engineering to join design and construction team as a bespoke metal fabricator and joiner.

Communal fine dining is easily the most unique aspect of the restaurant interior and represented the biggest challenge to the DesignLSM interior design team. We highly supported the designers and advised on the best solution from engineering and manufacturing point of view.

Our team was responsible to engineer, manufacture and fit exterior and interior cladding, bar and bar surrounds, bar gantry and rustic candle chandeliers and ornate candelabras. We also manufactured structural metal shelving, trims and ceiling gantry holders followed by the signage and decorational units.