The Brighton Dome is one of the UK’s most treasured cultural landmarks — a complex of heritage-listed buildings at the heart of Brighton’s Royal Pavilion Estate. Recently restored by Feilden Clegg Bradley Studios (FCBStudios), the project revitalises four Grade I and II listed buildings, breathing new life into their 19th-century architecture while ensuring the complex meets the demands of modern audiences and performers.

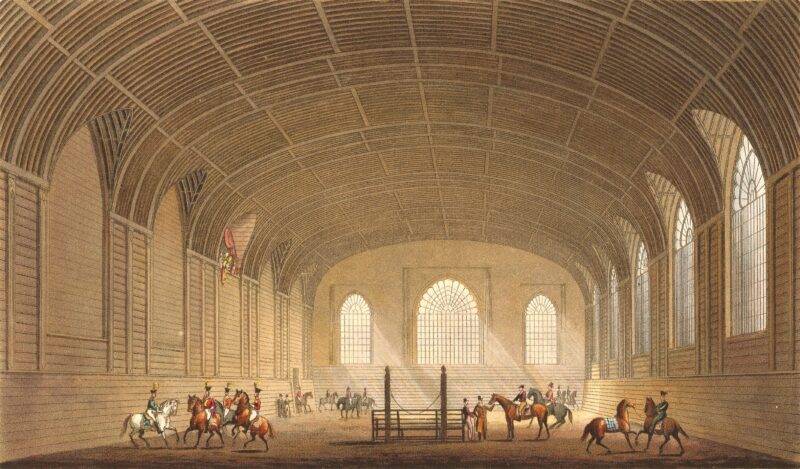

At the centre of the redevelopment stands the Corn Exchange, a magnificent Grade I listed building originally commissioned in 1803 as a riding house for the Prince Regent.

Over the centuries, it evolved into a celebrated performance space. The restoration sought to peel back layers of history, revealing original details while introducing contemporary materials and finishes that complement the building’s rich heritage.

To achieve this delicate balance between preservation and innovation, FCBStudios collaborated with a range of specialist craftspeople, including CDC Engineering, who were invited to bring their expertise in metal fabrication and architectural detailing to the project.

Our brief was to design, manufacture, and install bespoke metalwork that seamlessly integrates with both the historical fabric and the new architectural interventions. The goal was not only to replicate the precision and beauty of the original craftsmanship but also to embody the elegance and durability expected from a modern cultural venue.

At CDC Engineering, we pride ourselves on our attention to detail and mastery of metalwork. For the Brighton Dome refurbishment, our scope included:

Every element was meticulously manufactured in our in-house facilities in Shoeburyness, Essex, ensuring complete control over quality and precision. Working with mild steel allowed us to deliver a balance of strength, lightness, and versatility, crucial for such a large-scale architectural project.

Before installation, all fabricated components were black powder-coated in our on-site spray shop, achieving a durable, contemporary finish that complements the timber-rich interiors. The contrast between the sleek matte-black steel and warm oak surfaces embodies the project’s design philosophy, a refined dialogue between past and present.

The scale and complexity of the Brighton Dome meant our team had to combine engineering precision with adaptive craftsmanship.

Installation required close coordination with multiple contractors, as large cladding sections were fitted while other trades were actively working on site. Communication, planning, and flexibility were essential to ensure the project’s smooth progress and timely delivery.

Certain architectural components, due to their size and geometry, needed to be TIG welded directly on site by our skilled craftsmen. This process demanded not only technical proficiency but also a deep respect for the surrounding historic structure ensuring all work was executed with minimal disruption to the existing fabric.

Our engineers and fabricators brought a problem-solving mindset to every challenge, combining traditional hand skills with advanced fabrication techniques to achieve a flawless finish that met both aesthetic and structural expectations.

The completed Brighton Dome restoration showcases how heritage architecture and contemporary engineering can coexist beautifully. The essential conservation work undertaken by FCBStudios and the project team has restored hidden features, unveiled historic spaces, and introduced modern amenities that elevate the visitor experience.

New foyers, a top-lit bar, gallery spaces, and a restaurant opening onto New Road now connect the cultural complex to the wider city, while accessibility upgrades and improved circulation have made the venue more inclusive for audiences, performers, and staff alike.

For CDC Engineering, contributing to such a landmark project stands as a testament to our commitment to craftsmanship, precision, and collaboration. Our metalwork forms part of the building’s renewed identity, a contemporary layer that celebrates the past while looking confidently to the future.

Based in Shoeburyness, Essex, CDC Engineering specialises in architectural metalwork, structural fabrication, and bespoke design solutions for heritage restorations, commercial interiors, and large-scale public projects. Our dedicated team of engineers, welders, and fabricators combine technical expertise with artistic craftsmanship to deliver metalwork of the highest quality, designed, built, and finished in-house.